+27 87 265 0014 | info@envirovent.co.za | www.envirovent.co.za

DUST SUPPRESSION SYSTEMS

ENVIROVENT is an integrated solutions provider to the global mining, bulk material handling, mineral processing and beneficiation industries, offering innovative technological solutions as well as process and commodity knowledge along the industry value chains. The services range from system design, through to manufacture, turnkey installations and after-sales service, with expertise provided over a full range of environmental control and pneumatic conveying systems.

ENVIROVENT is a distributor for the DSI (Dust Solutions Incorporated) world-renowned range of prevention, suppression and wind protection products. Proven in applications stretching back more than 35 years, DSI have addressed breathable and visible problems for a wide array of industries including mining, power generation, biomass, aggregate, pulp and paper, wood products, hazardous waste, marine and bulk handling. Including locally based after-sales service.

DRY FOG SYSTEMS

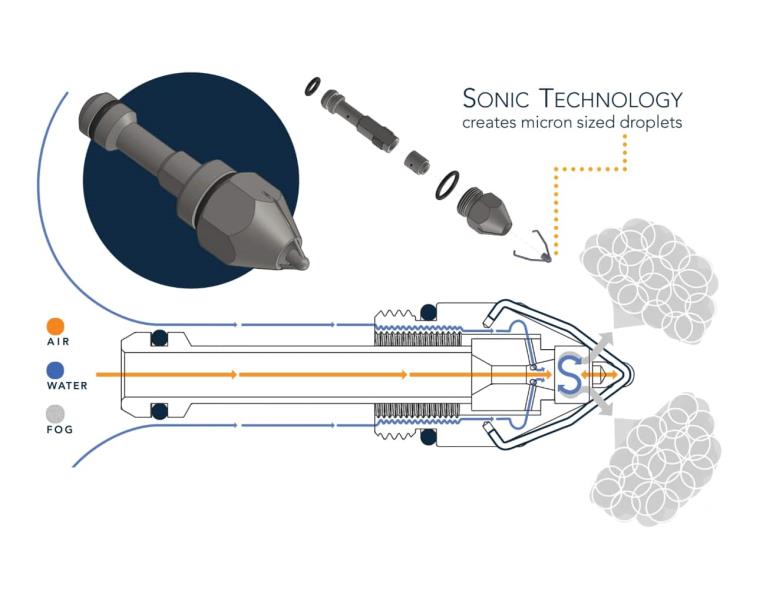

We create Dry Fog. Our technology uses air atomizing nozzles that produce water droplets 10 μm or less. These ultra-fine water droplets add less than 0,1 % moisture by weight and attach to like size dust particles and drop back into the process.

Our Dry Fog systems are designed and engineered to effectively reduce fugitive dust at material handling points.

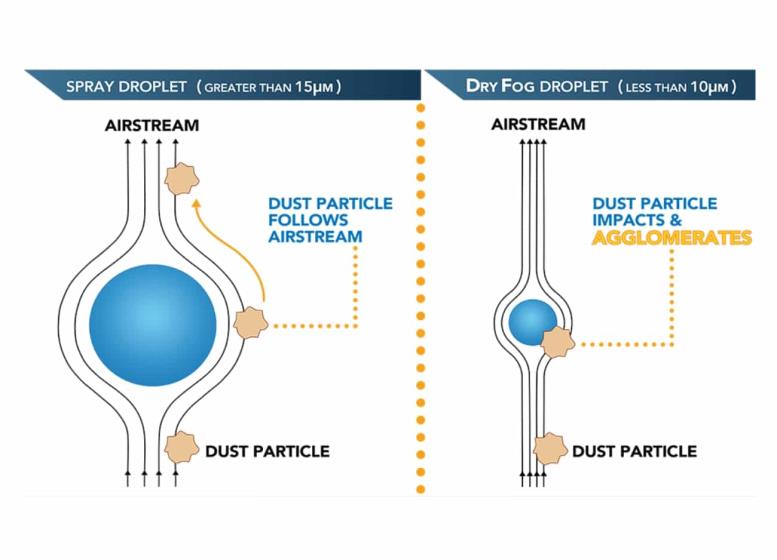

DRY FOG THEORY

The use of Dry Fog for dust suppression is based on the concept of agglomeration. Dry Fog technology uses compressed air and plain water to create micron sized droplets. When like-sized droplets and dust particles collide, agglomeration occurs which results in larger particles that fall back into the process by gravity because they are too heavy to remain suspended in the air.

To achieve agglomeration at the dust source, equal amounts of like sized particles of water droplets and dust particles must exist and they must be contained in an enclosed area.

At the treatment point, fog droplets are used to blanket the dust source and prevent the dust particles from becoming airborne.

DRY FOG PRODUCTS

We excel in designing solutions in challenging environments. The type of application, type of bulk material creating dust, and operating environments are considered when customising your system.

Our Dry Fog systems allow for flexible configuration with pre-assembled modular components. Housed in protective enclosures, we supply complete systems comprised of electrical controls, filtration, flow regulation, supply lines and nozzle mounts. If required, we can supply all ancillary items including air compressors, air receiver stations, pumps, and self-cleaning secondary filtration systems.

WHERE DOES IT WORK ?

Our Dry Fog systems significantly reduce fugitive dust from a variety of material handling points, including conveyor transfer points, trippers, reclaimers, crushers, screens, truck dumps, railcar loading / unloading, ship loaders / unloaders, and ash silo discharge chutes. Our systems can meet all requirements for explosion hazard areas. Freeze protection can be provided for systems operating in temperatures as low as – 60 degrees C.

WHAT ARE THE ADVANTAGES ?

Ease of installation, simplified maintenance, and flexible system configuration are just a few advantages of using Dry Fog to suppress dust. The overall capital investment and operating costs can be more affordable that the cost of ventilation and chemical type systems.

WIND FENCE DUSTTAMER™ SYSTEMS

Wind erosion causes an estimated 30 % of storage pile dust emissions. Reducing wind speed equates to less dust.

DustTamer™ reduces dust emissions caused from wind erosion on open stockpiles. Our wind fence material is designed to exert a drag force on oncoming wind and reduce wind speeds up to 75 % within the sheltered area. Our systems prevent dust that is generated by oncoming winds, material loading and unloading, and equipment and vehicle movement from becoming airborne.

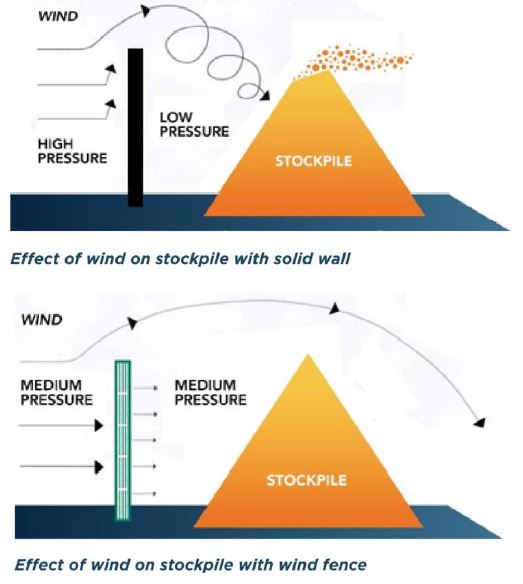

DUSTTAMER™ WIND FENCE THEORY

The concept behind how a wind fence works is easy to understand. If a solid wall is used as a wind break, two different pressure zones are created as wind movement towards the wall increases. Because impermeable materials, such as a solid wall only deflect wind, not reduce it, any openings for equipment access or areas on either side of the wall can funnel high pressure ambient air into the low pressure interior. This results in increased air velocities within the protected area. This will also cause wind to flow over the wall and create a turbulent movement on the other side, amplifying the wind speed and creating more particle uptake.

Conversely, if a porous material is used, high velocity wind that moves toward the stockpile will be diminished as the porosity will allow for air to pass through and equalise differential pressure on either side of the barrier.

WIND VELOCITY REDUCTION

The primary purpose of a wind fence is to reduce wind velocity moving towards the storage pile and prevent particle uptake in the protection zone. Particle movement can take place in three different ways: rolling, saltation, or suspension.

- Rolling / Creep: Rolling and sliding movement of larger particles along the ground. Depending on wind velocity, material can be moved to another pile.

- Saltation: Movement of particles by a series of short bounces along the ground which also dislodges additional particles with each impact.

- Suspension: Fine particles move parallel to the surface and upward into the atmosphere by strong winds. Particles can be carried high into the atmosphere, only returning to earth when wind subsides or they are carried down with precipitation. Suspended particles can potentially travel hundreds of kilometers.

DustTamer™ wind fence material is designed to exert a drag force on oncoming wind and reduce wind speeds up to 75 % within the sheltered area.

By controlling wind speeds, it is possible to control levels of particulate matter in the air. The material allows a portion of the wind volume to penetrate through the screen as well as deflect the remainder of the wind to the surrounding sheltered area. Subsequently, the velocity lowers to the point required to initiate particle movement and prevent suspension. Air passing through the screen is referred to as “displacement flow”. The displacement flow and wind velocity are determined by the permeability of the screen.

TOTAL WIND REDUCTION SYSTEMS

We supply all components for your DustTamer™ Wind Fence System:

- DustTamer™ Fabric is knitted from industrial grade woven polyester, resistant to UV rays, in-climate weather and temperature extremes. Its unique ability to be stretched and tensioned to over 2,2 kN of pull prevents “flagging” of the material and consequential damage due to abrasion. The slotted design prevents dust from plugging the fabric like basket weave material will do.

- Attachment hardware is comprised of specially designed galvanised stand-off metal brackets, lockbars and attachment screws to attach DustTamer™ material to your support columns. Attachment hardware enables tensioning and installation without the need for pre-drilling.

- Tie Wraps made of UV resistant nylon are the most common ties that we supply for tying runs of fabric together. This prevents the screen material from rubbing on an adjacent fabric run.

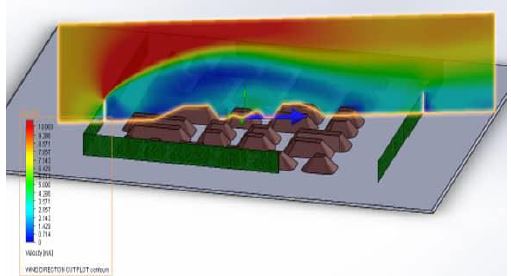

CFD MODELING FOR WIND FENCE DESIGN AND PLACEMENT

We use computational fluid dynamic (CFD) modeling to conduct in-depth engineering analysis of complex air and dust flow patterns that may be encountered at a project site.

By analysing conditions such as wind velocity, pressure, temperatures, topography and presence of existing structures, we accurately determine the location, fence structure height, and material porosity required to effectually reduce wind speeds and resulting particle uptake in a given area.

Using hard data, we design and plan for the most effective dust suppression mitigation solution possible.

NESCO SYSTEMS

Sometimes it is desirable to wet process material through a direct application of water. Our Water Spray Systems use a high-pressure pump and a variety of spray nozzles to add the right amount of water to your material.

This type of system is used at locations from conveyor stack outs to storage piles, and in processes where slightly wetting the process material is not a problem.

Some systems are equipped with modulating water regulators that are programmed to maintain the proper ratio of material process flow to water.

NESCO THEORY

Nesco spray systems control dust by producing a highly atomized mist that suppresses airborne particulates larger than 15 μm while adding from 0,2 % to 0,5 % moisture by weight to the process to prevent visible dust emissions from downstream unit operations. Water spray systems work on the principle of agglomeration for airborne dust, by producing water droplets that are the same size as the dust particles. These droplets collide with the dust particles and create larger particles that gravity brings back to the ground / process.

The key component with water sprays is that the smallest droplet possible on a high pressure water spray system is around 20 μm, which will be effective for visible and inhalable dust, but not respirable airborne dust. The downstream reduction of dust created by the moisture addition will reduce the creation of respirable and visible dust.

NESCO PRODUCTS

Nesco DustPro A Series (Automatic High Pressure Water Spray System)

The Nesco DustPro A Series features a 15 bar pump module that is controlled via a programmable logic controller which can be easily interfaced to plant control systems. The unit is equipped with rugged control valves, strainers, and heavy-duty brass piping for industrial use. It has fully automatic operation and can be equipped with air and glycol purges for cold weather operation. For portable operation, the unit can be mounted in an insulated trailer with heater, vent, fluorescent lighting, and all the necessary utility and hose feedthroughs. The Nesco DustPro A Series can be customised to accommodate any application. This includes additional water filtration, cold weather options, special control features, and additional alarm capabilities.

Nesco DustPro D Series (Duplex High Pressure Water Spray System)

The Nesco DustPro D Series features a 15 bar pump module that is controlled via a programmable logic controller which can be easily interfaced to plant control systems. The unit is equipped with dual redundant pumps for operating and standby that can be switched online. The DustPro D also contains rugged control valves, strainers, and heavy- duty brass piping for industrial use. The unit has fully automatic operation and can be equipped with air and glycol purges for cold weather operation. For portable operation, it can be mounted in an insulated trailer with heater, vent, fluorescent lighting, and all the necessary utility and hose feedthroughs. The Nesco DustPro D Series can be customised to accommodate any application. This includes additional water filtration, cold weather options, special control features, and additional alarm capabilities.

Nesco DustPro M Series (Manual High Pressure Water Spray System)

The Nesco DustPro M Series features a 15 bar pump module that is manually operated. The unit is equipped with rugged manually operated control valves, strainers, and heavy-duty brass piping for industrial use. For portable applications, the unit can be mounted in an insulated trailer with heater, vent, fluorescent lighting, and all the necessary utility and hose feedthroughs. The Nesco DustPro M Series can be customised to accommodate any application, including additional water filtration, cold weather options, special control features, and additional alarm capabilities.

Nesco DustPro HP Series (High Pressure Misting System)

The Nesco DustPro HP Series features a 70 – 90 bar seal less pump module that is controlled via a programmable logic controller which can easily interface to a plant automation system. The seal less pump allows the pump to run dry with no damage incurred by the pump. The unit is equipped with rugged control valves, strainers, and heavy-duty brass piping for industrial use. It has fully automatic operation and can be equipped with air and glycol purges for cold weather operation. For portable applications, the DustPro HP can be mounted in an insulated trailer with heater, vent, fluorescent lighting, and all the necessary utility and hose feedthroughs. The Nesco DustPro HP Series can be customised to fit the clients application. This includes additional water filtration, cold weather options, special control features, and additional alarm capabilities.

Nesco Wheel Wash 72 (Automatic High Pressure Wheel Wash System)

Dual Spray Manifolds: Two 5 meter horizontal 1-1/2” galvanised steel spray bars each with 14 brass nozzles are designed to wash tires one full rotation. Includes mounting bracket and 25 meters of 1-1/2” hose.

Control Panel and Sensor for Auto Operation: Reflective presence detector in armored housing on adjustable swivel mount automates wheel wash operation. Nema 4X control panel with power disconnect switch, GFI, control relay, timers, terminal blocks, fuses, one 2-position power switch, one 3-position MANUAL / OFF / AUTO switch for setting operating mode. Second Nema 4X enclosure houses solenoid and drain valves with self-regulating heat tape.

Nesco Wheel Wash 200 (Manual High Pressure Wheel Wash System)

Pump Module: 760 l/min., 6 bar, 11 kW pump boosts water pressure to improve cleaning efficiency and reduce water consumption.

Dual Spray Manifolds: Two 5 meter horizontal spray bars hung off of barricade blocks are designed to wash tires through one full rotation.

Sensor: Choice of an in-ground magnetic induction loop or above ground sensor automates wheel wash operation.